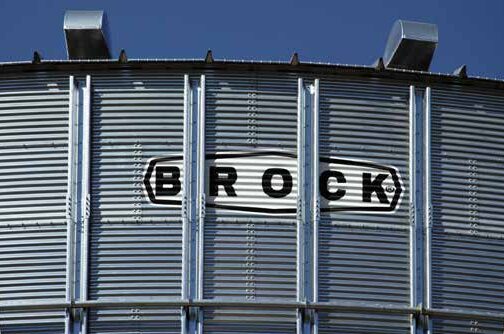

EVEREST® Grain Bins Are the Pinnacle of Grain Storage Innovation

Elevate your grain storage to greater heights and larger capacities! Brock’s EVEREST® Grain Bins offer the tallest eave heights in the industry along with higher grain-holding capacities to help meet the storage challenges presented by trend-line grain yield increases.

In addition to scaling to greater heights and the capacity to store more grain, the EVEREST Bin design features innovative changes to the roof structure, body sheets, bin stiffeners, anchoring systems and accessories while also meeting or exceeding new grain industry standards.

More

EVEREST® Grain Bin models are 15 to 156 feet (4.6 to 47.5 m) in diameter and offer a range of storage capacities of 2,978 to 1,939,574 bushels (99 to 64,480 cubic meters), offering you some of the highest capacities in the industry.

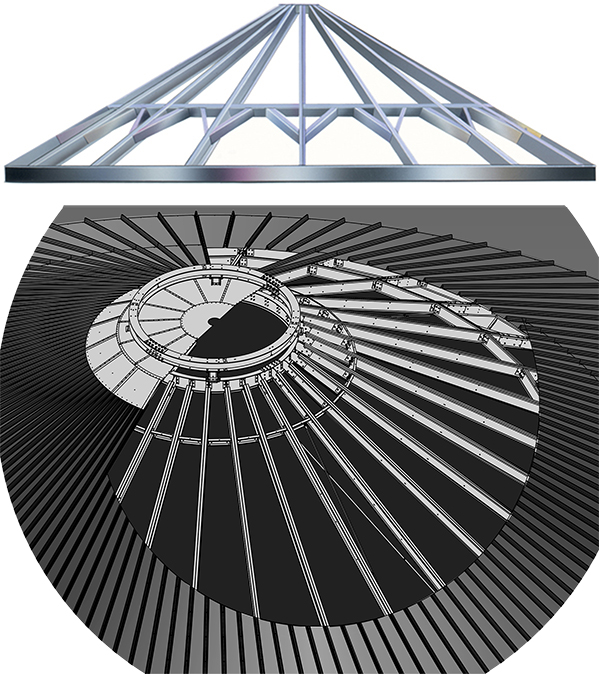

The EVEREST Bin line offers greater roof peak loading capacities – up to 130,000 pounds (59,000 kg) with a uniformly-distributed pure vertical load depending on bin diameter and model. This load capacity is based on 30 pounds per square foot (146 kg per square meter) ground snow load.

Take a closer look at the BrockReady™ pre-engineered benefits of a Brock EVEREST® Bin roof peak. Brock’s unique EVERLOC® Roof Mount System is available to efficiently and uniformly connect the bin with LeMar® Catwalk and Tower Support Systems. This exclusive system provides pre-designed connection points that integrate with LeMar products, ensuring uniform weight distribution of rooftop equipment across the roof structure and allowing for future expansion.

What are the benefits provided by the EVERLOC Roof Mount System?

- Higher Load Capacities – The EVERLOC Roof Mount seamlessly transfers loads to the bin roof’s integrated compression ring.

- Efficient Connections – EVERLOC Roof Mount efficiently connects EVEREST® Bins with Brock’s LeMar® Catwalks and Tower Support Systems.

- Accommodate Movement – Slip connections allow for movement between the bin peak and catwalk, preventing structural damage.

- Leak-Free Installation – With EVERLOC® Mounts, the roof sheet is sandwiched between two pre-drilled weldments providing a fully galvanized bolt-together design. This saves time and labor during installation by eliminating the traditional practice of cutting and resealing holes in the bin roof in order to install equipment at the roof peak.

- Safe Roof Access – Optional Bin Peak Walk-around provides safe access for equipment inspection and maintenance.

- Less On-Site Millwright Work – Pre-engineered conveyor supports provide easy installation of equipment.

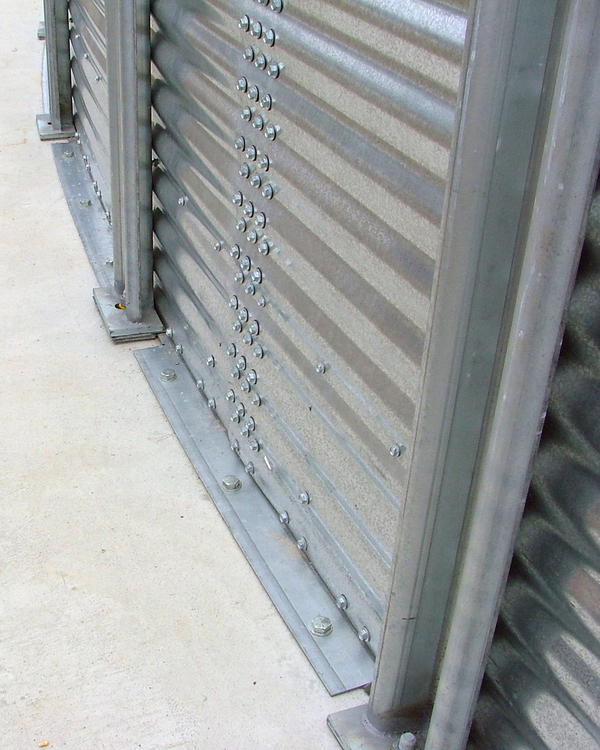

The EVEREST Bin’s sidewalls defend stored grain from the weather while also providing critical strength components vital to the bin’s structure:

- Efficient vertical seam patterns provide improved strength for body sheet connections in both narrow- and wide-corrugation bin models.

- Thicker body sheets (up to 5 gauge) resulting in fewer laminated sidewall panels and more efficient use of optimal sidewall thicknesses at all levels of the bin.

- Standardized 3/8-inch (9.5-mm) diameter bolts on narrow-corrugation sidewall connections provide more efficient connections and fewer hardware sizes in assembly.

- JS1000™ bolt coating contributes improved bolt life expectancy and corrosion protection.*

Brock’s sidewall stiffeners are among the strongest and the most efficient available to help bins manage the stress and strain of weather, stored grain, temperature cables and roof-mounted equipment. The bolt hole patterns used for the EVEREST Bin’s stiffener design provide more efficient connections, ensure stiffener alignment and increase strength for:

- Improved handling of internal forces and pressures generated by the grain.

- Taller bin models offering more grain capacity — nearly 14% more storage capacity when compared with previous grain bin models that have the same diameter footprint.

- Higher roof peak weight loads.

- Brock’s innovative HERCULES® Support System utilizes the bin’s sidewall stiffeners as LeMar® Support Tower connections.

Further strength is provided by the grain bin foundations, which are designed to secure the bins against 105 mph (169 km/h) winds.

*The JS1000 trademark is not owned or licensed by CTB, Inc.

LATCH-LOCK® Walk-Through Bin Door

Why struggle to squeeze through a small, tight opening when you could just open a door to walk into your grain bin for inspections? A standard feature on all EVEREST Bins is Brock’s LATCH-LOCK® Walk-Through Bin Door. This two-ring tall galvanized steel door makes entering even the largest grain bins easy:

- The one-piece outer door opens wide to latch securely against the side of the bin.

- The door’s three or four inner panels open in sequence from top to bottom with a simple lift of the patented latches. No tools are required.

- Meets recommendations for bin entry, rescue and safety standards.

Ladder Security Door and LATCH-LOCK® One-Ring Door

To aid producers in their biosecurity measures, Brock has developed a ladder lock-out system. This Ladder Security Door helps to restrict unauthorized access to the outside ladder on grain storage or feed bins and silos.

A one-ring (tier) LATCH-LOCK® Door is available on BROCK® flat-bottom grain bins and is standard on Brock’s EVEREST Hopper-Bottom Holding Bins.

Other Safety Features

- Manhole Surround

- Mid-Roof Stairs Platforms

- Safety Gates on Roof Platforms

- Ladder Safety Cages

- Center Compression Ring and Interior Perimeter Anchor Points for In-Bin Safety

Brock’s unique FULL SWEEP® Bin Anchoring System (patented) allows for the safe operation of single-pass sweeps in all Brock EVEREST Grain Storage Bins:

- A standard feature on all bins 72 feet (22 m) in diameter and larger.

- Safely handles normal bin stresses generated during single-pass sweep operation.

- Saves time, reduces labor and eliminates the need for bin entry during the sweep process.

- Firmly reinforces the bottom-tier sidewall body sheet to anchor the bin and to prevent moisture penetration.

Industry-Leading 5-Year Warranty*

*See Brock’s full written warranty for complete warranty details.

EVEREST® Narrow Corrugation – All Diameters

EVEREST® Wide Corrugation – All Diameters

* Maximum Capacity (Peaked) for a bin/silo allows for grain to be at a 28-degree angle of repose, starting one inch (25 mm) below the eave. The grain capacities listed above are based on ASAE Standard: ASAE S413.1, with a compaction factor of 6%. Metric tons are based on the ASAE standard of 721 kg per cubic meter for corn and 772 kg per cubic meter for wheat. Bins/silos are designed to meet code requirements for 105 mph (169 km/h) wind zones and seismic zone 1. Standard roof peak capacities vary from 2,500 to 130,000 pounds (1,100 to 59,000 kg) depending on silo diameter. In the pursuit of LEADERSHIP THROUGH INNOVATION®, we reserve the right to change specifications without prior notice.

¹ Some stiffened bins/silos 48 and 54 feet (14.6 and 16.5 m) in diameter require a temperature cable package to be added during construction if temperature cables are desired.

² Fill height for 48-foot (14.6-m) diameter bins with economical four-panel roof option. Brock's structured roof is standard on all bins/silos 54 feet (16.5 meters) in diameter and larger.

Because you will customize your grain storage system to your unique needs, not all potentially dangerous or harmful situations can be identified by Brock Grain Systems at the time the silo components and accessories are manufactured. Therefore, it is essential that you think safety first and pay close attention to all possible hazards

Brock Solid Grain Storage BR-2275-202201 (904.93kB)

Brock Solid Grain Storage BR-2275-202201 (904.93kB) Brock Solid EVEREST® Storage Bins BR-2273-202301 (0.95MB)

Brock Solid EVEREST® Storage Bins BR-2273-202301 (0.95MB) Brock Solid Capacities For EVEREST® Bins BR-2287-202407 (1.05MB)

Brock Solid Capacities For EVEREST® Bins BR-2287-202407 (1.05MB) Silos Comerciales para el Almacenamiento de Granos BR-2059-0411-ES (562.3kB)

Silos Comerciales para el Almacenamiento de Granos BR-2059-0411-ES (562.3kB) Металлические силоса с плоским дном BR-2059-RU-0810 (533.9kB)

Металлические силоса с плоским дном BR-2059-RU-0810 (533.9kB) Brock Solid Commercial Bin Anchoring System BR-2054-202108 (491.2kB)

Brock Solid Commercial Bin Anchoring System BR-2054-202108 (491.2kB) Brock Solid Bin Roof Safety Walkarounds BR-2346-202301 (1.16MB)

Brock Solid Bin Roof Safety Walkarounds BR-2346-202301 (1.16MB)