Safe & Reliable Bucket Elevators That Are Easy to Maintain

Brock provides a variety of bucket elevators to help you deliver grain or other material to the farthest reaches of your handling and storage system. From whole grains to feed to fertilizer, Brock helps you get your product where it needs to go.

The Brock bucket elevator line is designed with the operator in mind for safety, easy maintenance, and trouble-free operation. Brock offers standard bucket elevators up to 60K BPH and custom sizes up to 80K BPH to meet your specific needs.

More

- Solid-welded flange connections provide extra durability. Brock equipment is not stitch-welded like some of the competitors.

- Boot hoppers available with 1/4-inch (6.4 mm) abrasion resistant steel liner on BE36 to BE48 models. Optional on BE18 to BE30 models.

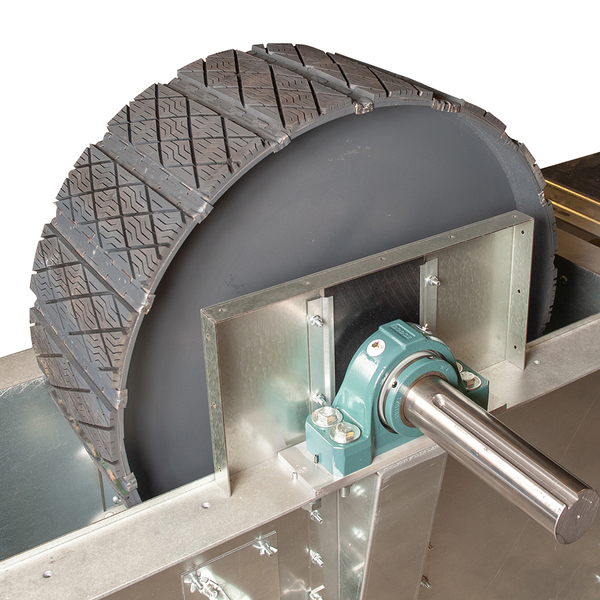

- Pillow block bearings on head and boot resist deflections and don’t transfer heat like flange bearings. Meets NFPA code requirements.

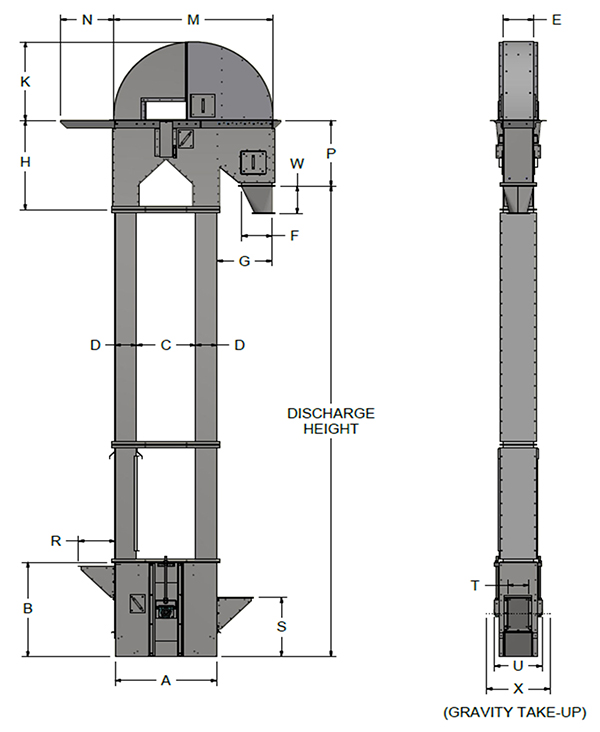

The bonnet discharge throat and profile helps elevated materials to discharge properly and minimize material that travels back down the return leg (back-legging).

- Trunking components are fixture welded to ensure square and parallel trunking for easy field assembly.

- Removable inspection doors on both sides of the up casing aid quick installation and maintenance of belting and buckets.

- Brock’s gravity take-up boots are offered with 18-, 24-, 30-, 36-, 42- and 48-inch (457-, 610-, 762-, 914-, 1067- and 1219-mm) pulleys.

- Elevator finish can be galvanized or stainless steel.

- Shaft made of #1045, turned, ground and polished steel. Boot shafts are drilled and tapped for optional motion monitor.

- Main head assembly has a 1/2-inch (12.7-mm) lip above the frame to provide a dust-tight and weatherproof seal. Split removable bonnet offers easy access.

- Adjustable throat baffle is designed for maximum discharge.

- Wear points in head and bonnet are lined. Available liners include urethane, abrasion-resistant (AR) steel and ceramic tile.

- Dust-tight and weatherproof shaft seals.

- Inspection and maintenance ports have gasket seals.

- Belting can be furnished in PVC or rubber.

- Screw take-up is standard in the boot section. External gravity take-up is optional.

- Safety cable is standard on all head access doors.

- Many other options available: service platforms, ladders, safety cage, guy brackets and explosion relief vents.

- Optional stainless steel elevator boot feet are ideal for pit and other corrosive environment applications.

Durable Belt Fastener with “one size fits all” belts and pulleys. Each splice set joins a 2-inch (50.8-mm) wide belt area.

Relief panels release pressure from possible explosion. Safety cable prevents panel from falling.

The speed monitor mounts to the elevator boot shaft to detect slowdown in belt speed, indicating a plug situation. Available in single set point and dual set point, less control cable.

#1 Norway Elevator bucket bolts with nuts are sold (in quantities of 100) in 1-inch (25.4-mm) through 2-inch (50.8-mm) long, standard and fanged variety along with 1/4-inch (6.4-mm) and 5/16-inch (7.9-mm) lock washers, flat washers and hex nuts are available.

High intensity magnet is mounted in elevator boot hopper to remove tramp metal. Quick release clamps allow for easy cleaning.

PVC (standard) or rubber (optional) belts are available.

Polyethylene buckets standard. Metal, urethane or nylon buckets are optional. Bucket venting optional for fine or light weight products.

High quality urethane liners with expanded metal backing are available in: 1/4-inch (6.4-mm) urethane, 1/4-inch (6.4-mm) ceramic chip urethane or 5/16-inch (7.9-mm) high energy urethane.

Motors up to 150 horsepower are available from stock. Motors are 1725-1800 RPM 60 Hz and 1450 RPM 50 Hz, three phase. Enclosures are TEFC or Explosion Proof, Class II, Group G.

A boot shovel hopper is available on all Brock bucket elevators. The shovel hopper has a hinged cover and a grate over the opening. The shovel hopper is located on the down leg side.

Elevator pulleys are available in drum, winged and spiral winged styles.

Heavy-duty slide lagging (SOF Style 5) slides into retainers which are welded onto the pulley.

Gravity take-up for automatic belt tension is available on all Brock bucket elevators. Included is a weight box and alignment bolts for tracking the elevator belt.

Self-cleaning boot holds close clearance between boot bottom and cups at all times.

Mounts directly to head section. Available in 1,000-lb. (454-kg) and 1,500 lb. (681 kg) capacities.

Bucket Elevator Capacities

| Model | Capacity* | Bucket Size |

|---|---|---|

| BE180912-013 | 1,350 bph (37 mtph) | 9 x 5 in. (229 x 127 mm) |

| BE180912-017 | 1,750 bph (48 mtph) | 9 x 5 in. (229 x 127 mm) |

| BE180912-020 | 2,000 bph (54 mtph) | 9 x 5 in. (229 x 127 mm) |

| BE180912-026 | 2,650 bph (72 mtph) | 9 x 5 in. (229 x 127 mm) |

| BE241013-030 | 3,000 bph (82 mtph) | 9 x 6 in. (229 x 153 mm) |

| BE241013-035 | 3,500 bph (95 mtph) | 9 x 6 in. (229 x 153 mm) |

| BE301014-033 | 3,300 bph (90 mtph) | 9 x 6 in. (229 x 153 mm) |

| BE301014-036 | 3,600 bph (98 mtph) | 10 x 6 in. (254 x 153 mm) |

| BE301014-042 | 4,200 bph (114 mtph) | 10 x 6 in. (254 x 153 mm) |

| BE301017-045 | 4,500 bph (123 mtph) | 12 x 6 in. (305 x 153 mm) |

| BE301017-050 | 5,000 bph (136 mtph) | 13 x 6 in. (331 x 153 mm) |

| BE301017-057 | 5,700 bph (155 mtph) | 13 x 6 in. (331 x 153 mm) |

| BE361117-061 | 6,100 bph (166 mtph) | 12 x 7 in. (305 x 178 mm) |

| BE361117-070 | 7,000 bph (191 mtph) | 13 x 7 in. (331 x 178 mm) |

| BE361117-079 | 7,900 bph (215 mtph) | 13 x 7 in. (331 x 178 mm) |

| BE361120-081 | 8,160 bph (222 mtph) | 15 x 7 in. (381 x 178 mm) |

| BE361120-085 | 8,500 bph (231 mtph) | 16 x 7 in. (407 x 178 mm) |

| BE361120-100 | 10,000 bph (272 mtph) | 16 x 7 in. (407 x 178 mm) |

| BE421321-104 | 10,440 bph (284 mtph) | 14 x 8 in. (356 x 204 mm) |

| BE421321-123 | 12,350 bph (336 mtph) | 16 x 8 in. (407 x 204 mm) |

| BE421323-136 | 13,650 bph (372 mtph) | 18 x 8 in. (458 x 204 mm) |

| BE421323-152 | 15,200 bph (414 mtph) | 18 x 8 in. (458 x 204 mm) |

| BE421325-157 | 15,750 bph (429 mtph) | 20 x 8 in. (508 x 204 mm) |

| BE481425-151 | 15,100 bph (411 mtph) | 18 x 8 in. (458 x 204 mm) |

| BE481435-207 | 20,700 bph (564 mtph) | (2) 14 x 8 in. (356 x 204 mm) |

| BE481439-250 | 25,000 bph (681 mtph) | (2) 16 x 8 in. (407 x 204 mm) |

| BE481443-300 | 30,000 bph (817 mtph) | (2) 18 x 8 in. (458 x 204 mm) |

| BE481447-350 | 35,000 bph (953 mtph) | (2) 20 x 8 in. (508 x 204 mm) |

Bucket Elevator Capacities Note

| *Capacities based on water level plus 10% for dry, free flowing, grains with a 48 lb/ft³ (768 kg/m³) material density |

|---|

Brock Solid Grain Handling BR-2277/202203 (888.88kB)

Brock Solid Grain Handling BR-2277/202203 (888.88kB) Brock Solid Bucket Elevators BR-2292-202203 (1.48MB)

Brock Solid Bucket Elevators BR-2292-202203 (1.48MB)