GO WITH THE FLOW with the VECTOR® Energy Miser® Mixed Flow Dryer from Brock.

Finally, a mixed flow dryer that actually flows. The VECTOR® ENERGY MISER® Mixed Flow Dryer is designed with many innovative features that improve grain flow for efficient moisture removal and gentle grain handling.

VECTOR® Energy Miser® Mixed Flow Dryer Video

More

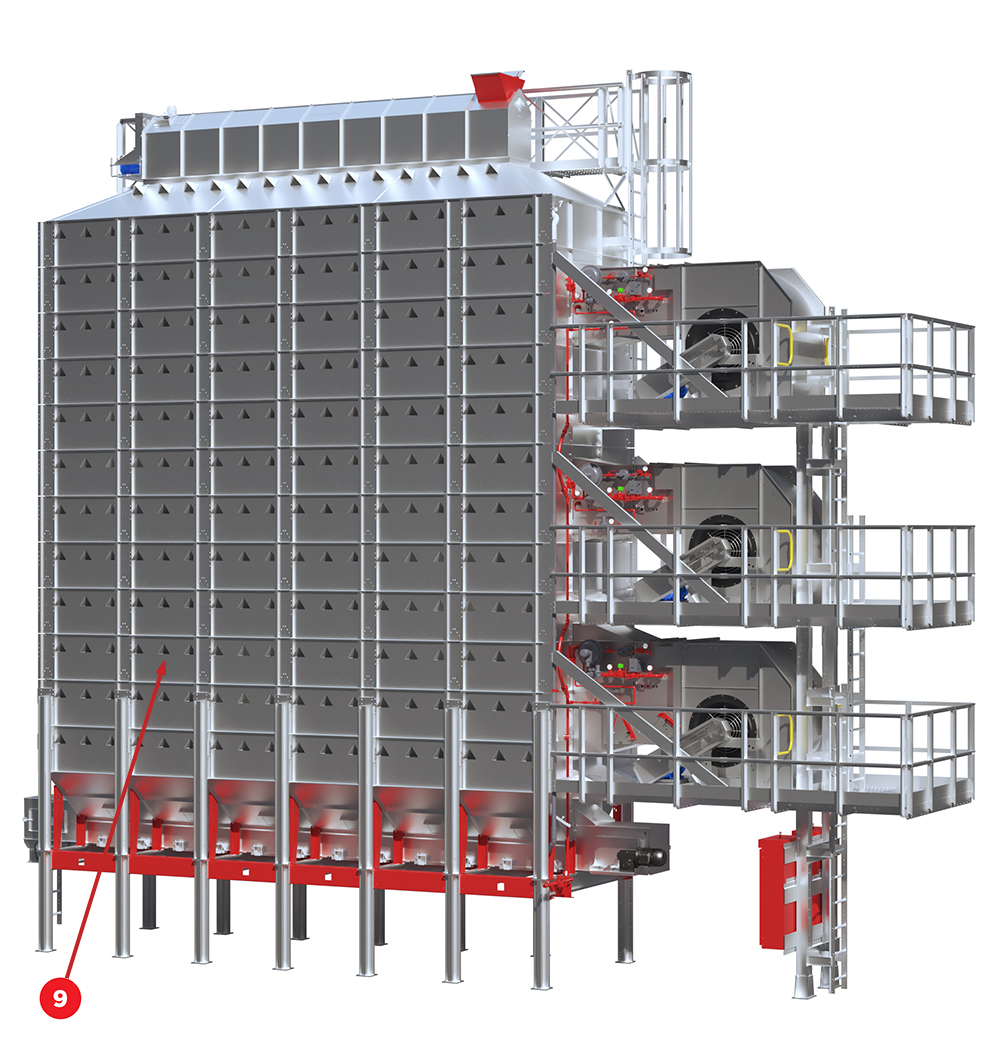

The VECTOR® Dryer is the only mixed flow dryer that mixes two grain columns into one using a single unload. Grain is evenly metered and gently moved away from the column using the proven Brock EVENFLO® Dryer Unloading System. It reduces moving parts, maintenance and plugging risks associated with metering rolls.

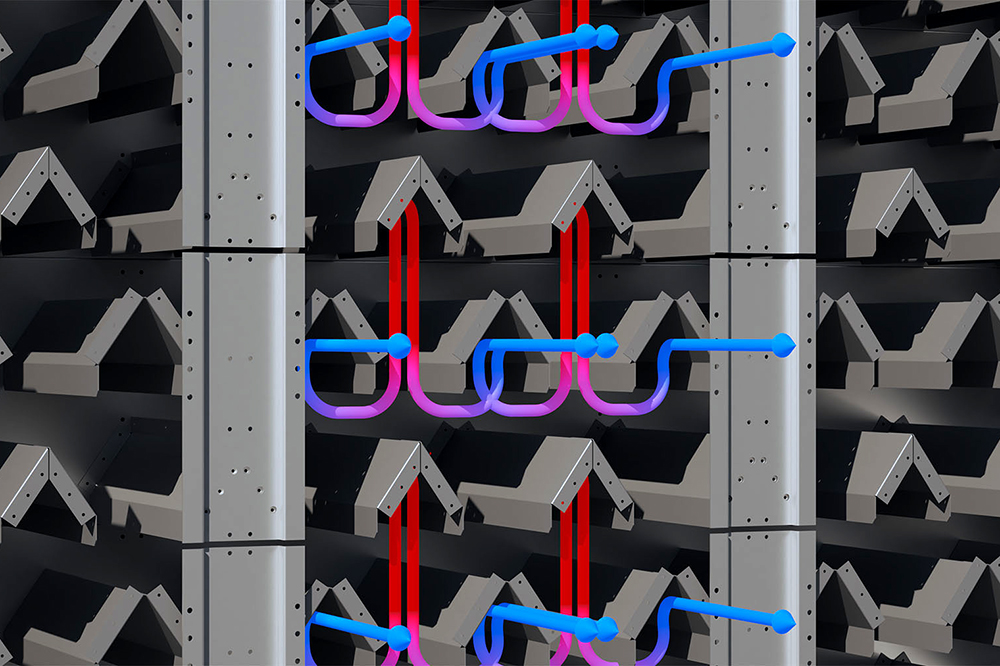

The patent-pending, innovative FLOW OPTIMIZER® Grain Column Equalizer ensures even flow of grain across the width of the column, enabling more consistent kernel moisture content throughout the dryer.

A series of triangular-shaped ducts mix kernels and distribute heated air evenly across the grain as it flows through dual columns.

Brock’s exclusive TrueGrain™ System passes grain through a parallel sensing field in a fixed vertical chamber that isolates outside factors. This allows your dryer to output more accurate grain moisture levels and more consistent profitability.

Proven drying algorithms and straightforward controls take grain drying to the next level. Remote monitoring of Brock’s INTUI-DRY® Dryer Controller gives enhanced access through a smartphone, tablet or laptop computer — for monitoring and controlling the dryer system anytime, nearly anywhere.

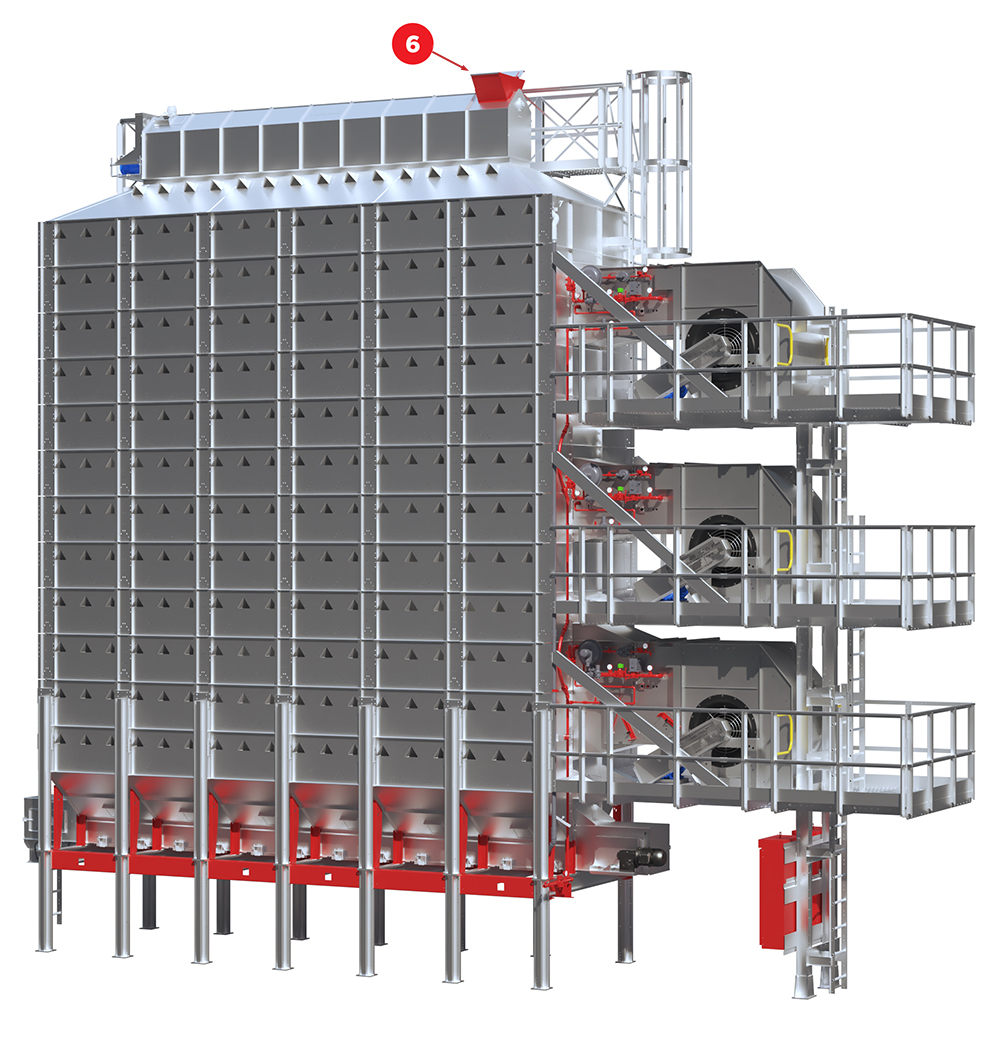

You can fill the VECTOR® Dryer with gravity flow or select our leveling auger fill system for installation flexibility. Leveling auger option shown.

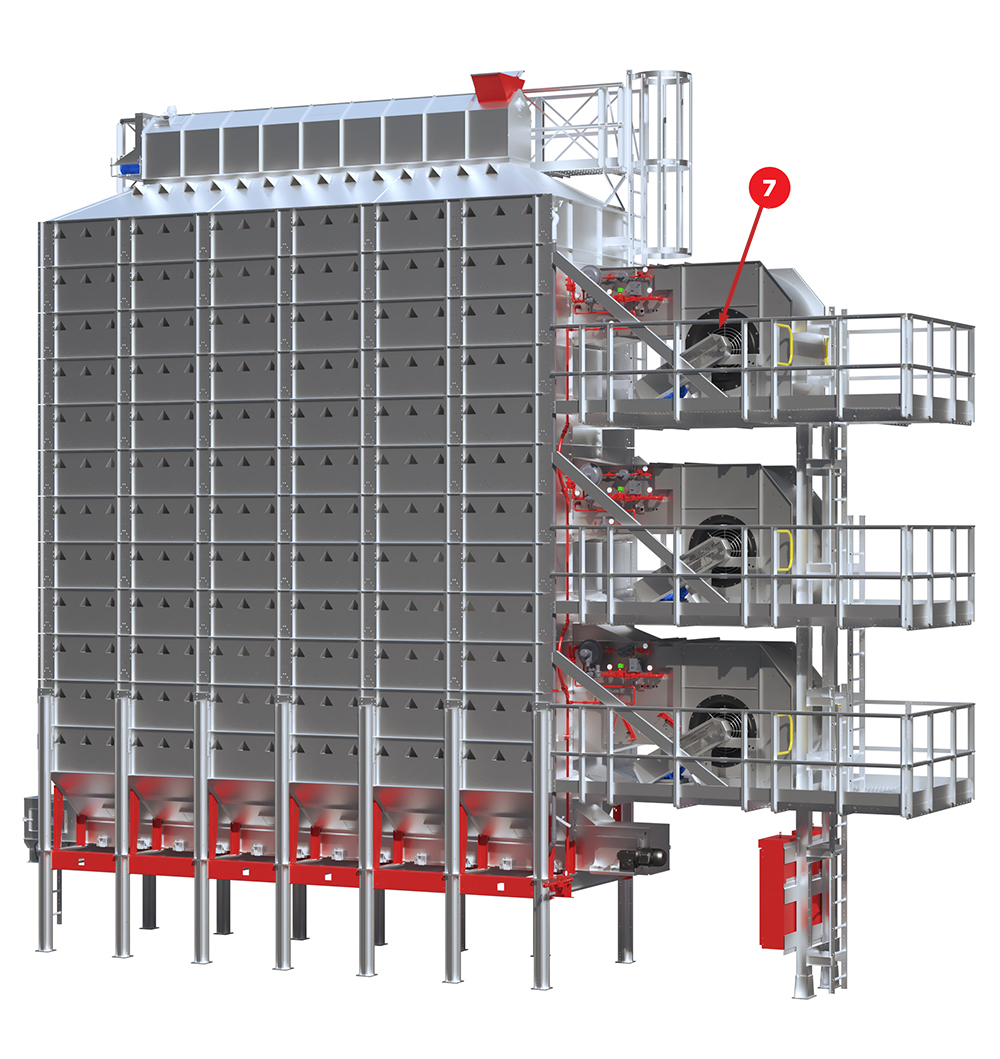

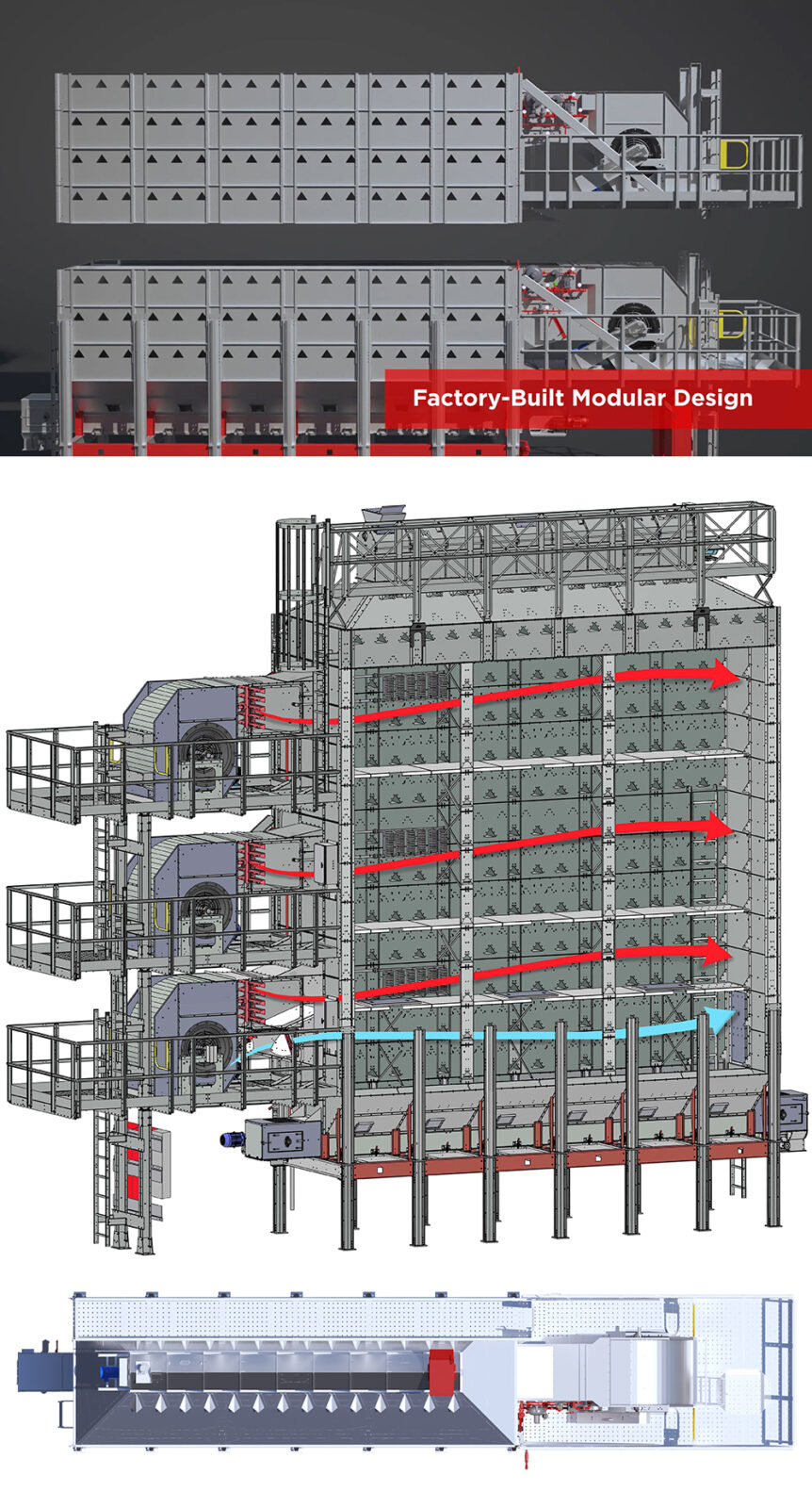

Double-Wide, Double- Inlet centrifugal blowers maximize airflow while minimizing sound levels.

Full flame wall burners more evenly heat the air for better efficiency and more uniform drying.

Screenless exhaust ducts reduce cleaning maintenance on the exterior of the dryer.

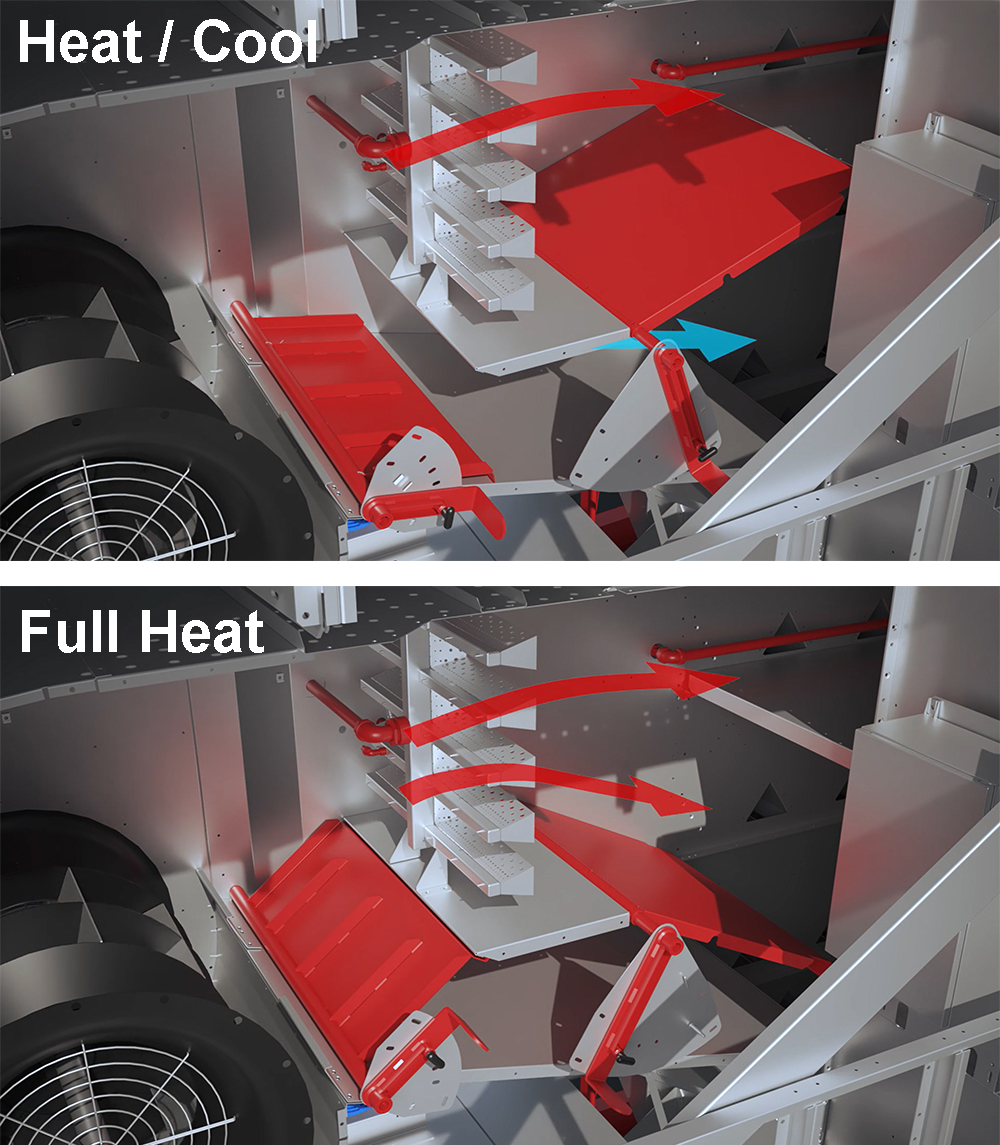

Brock includes a convenient air diverter that lets you easily change between full heat drying or heat and cool mode.

Stackable modules feature independent heating for multi-zone temperature control. Factory-built modular design and plug-and-play wiring allows VECTOR Dryers to be installed quickly and efficiently.

VECTOR® Dryer

| Dryer Model | 1608 | 1610 | 1612 | 1614 | 2408 | 2410 | 2412 | 2414 | 2416 | 2420 |

|---|---|---|---|---|---|---|---|---|---|---|

| Dryer Width | 8.8 ft. (2.7 m) | 8.8 ft. (2.7 m) | 8.8 ft. (2.7 m) | 8.8 ft. (2.7 m) | 8.8 ft. (2.7 m) | 8.8 ft. (2.7 m) | 8.8 ft. (2.7 m) | 8.8 ft. (2.7 m) | 8.8 ft. (2.7 m) | 8.8 ft. (2.7 m) |

| Grain Column Length | 16 ft. (4.9 m) | 16 ft. (4.9 m) | 16 ft. (4.9 m) | 16 ft. (4.9 m) | 24 ft. (7.3 m) | 24 ft. (7.3 m) | 24 ft. (7.3 m) | 24 ft. (7.3 m) | 24 ft. (7.3 m) | 24 ft. (7.3 m) |

| Number of Tiers | 8 | 10 | 12 | 14 | 8 | 10 | 12 | 14 | 16 | 20 |

| Overall Dryer Length | 34.9 ft. (10.6 m) | 34.9 ft. (10.6 m) | 34.9 ft. (10.6 m) | 34.9 ft. (10.6 m) | 42.8 ft. (13.0 m) | 42.8 ft. (13.0 m) | 42.8 ft. (13.0 m) | 42.8 ft. (13.0 m) | 42.8 ft. (13.0 m) | 42.8 ft. (13.0 m) |

| Dryer Fill Height - Gravity Garner | 28.8 ft. (8.8 m) | 32.8 ft. (10.0 m) | 36.8 ft. (11.2 m) | 40.8 ft. (12.4 m) | 30.8 ft. (9.4 m) | 34.8 ft. (10.6 m) | 38.8 ft. (11.8 m) | 42.8 ft. (13.0 m) | 46.8 ft. (14.3 m) | 54.8 ft. (16.7 m) |

| Dryer Fill Height - Leveling Auger | 29.3 ft. (8.9 m) | 33.3 ft. (10.1 m) | 37.3 ft. (11.4 m) | 41.3 ft. (12.6 m) | 29.3 ft. (8.9 m) | 33.3 ft. (10.1 m) | 37.3 ft. (11.4 m) | 41.3 ft. (12.6 m) | 45.3 ft. (13.8 m) | 53.3 ft. (16.2 m) |

| Double-Wide, Double-Inlet Blower (Quantity x hp) | 2x 15 hp | 2x 15 hp | 2x 20 hp | 3x 15 hp | 2x 20 hp | 2x 20 hp | 3x 20 hp | 3x 25 hp | 4x 20 hp | 5x 20 hp |

| Max Burner Output (Million BTU/hr) | 6.0 | 8.4 | 10.2 | 12.4 | 9.2 | 11.0 | 15.3 | 17.1 | 21.4 | 24.8 |

| Typical Burner Output (Million BTU/hr) | 4.6 | 6.5 | 7.9 | 9.6 | 7.1 | 8.6 | 11.9 | 13.2 | 16.6 | 19.3 |

| Leveling Auger Load Motor Size | 3 hp | 3 hp | 3 hp | 3 hp | 5 hp | 5 hp | 5 hp | 5 hp | 5 hp | 5 hp |

| Unload Motor Size | 3 hp | 3 hp | 3 hp | 3 hp | 3 hp | 3 hp | 3 hp | 3 hp | 3 hp | 3 hp |

| Total Corn Holding Capacity (bu) | 1,044 | 1,250 | 1,469 | 1,687 | 1,588 | 1,915 | 2,242 | 2,570 | 2,897 | 3,552 |

| *Estimated Drying Capacity Corn Dry/Cool 20% to 15% (bph) | 784 | 962 | 1,177 | 1,413 | 1,180 | 1,352 | 1,766 | 2,003 | 2,446 | 2,900 |

| *Estimated Drying Capacity Corn Dry/Cool 25% to 15% (bph) | 431 | 579 | 700 | 792 | 647 | 775 | 1,052 | 1,110 | 1,375 | 1,621 |

| *Drying capacities are estimates based on collected field test data. These capacities should be attainable in one pass with mature, unfrozen, clean (maximum 2% fines) grain when operating the dryer at the recommended drying temperature. Drying capacities will vary depending upon weather conditions, hybrid variety, grain maturity, and cleanliness of the grain. |

||||||||||

Brock Solid VECTOR® ENERGY MISER® Mixed Flow Dryer BR-2373-202411 (626.29kB)

Brock Solid VECTOR® ENERGY MISER® Mixed Flow Dryer BR-2373-202411 (626.29kB)